2026 How to Choose the Right Overhead Coiling Door for Your Business?

When selecting the right overhead coiling door for your business, many factors come into play. This door offers security and accessibility, but not all options suit every need. Think about the size of your entrance and the type of traffic it will face. Will heavy machinery be passing through?

Durability is key. Your overhead coiling door should withstand wear and tear. Consider materials like steel or aluminum, which provide strength. A reliable door can prevent costly repairs down the line.

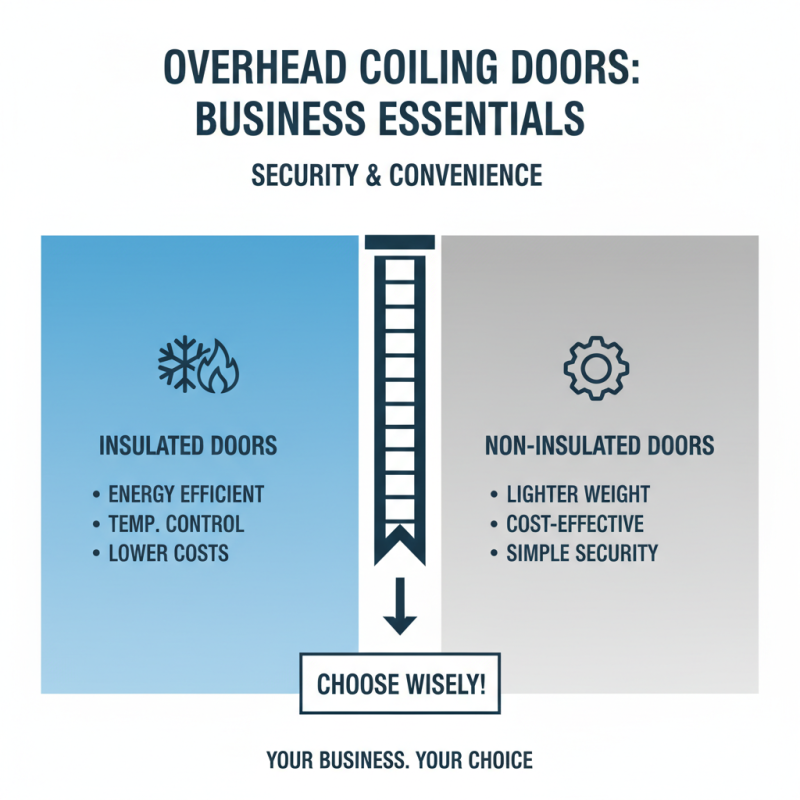

Flexibility also matters. Different businesses have varying requirements. Some may require insulation, while others need speed in operation. An inappropriate choice can lead to inefficiencies. Take time to assess your needs before making a decision.

Understanding Overhead Coiling Doors: Types and Benefits

Overhead coiling doors are an essential element in many businesses. They provide security and convenience. Understanding the types and benefits can help in making the right choice. There are two main types: insulated and non-insulated doors. Insulated doors offer energy efficiency. They help maintain temperature and reduce energy costs. Non-insulated doors are often lighter and more cost-effective.

When choosing a door, consider the specific needs of your business. Think about the size and weight of the door. It's important to ensure that it fits the space correctly. Location matters too. Doors exposed to harsh weather may need additional protection. Evaluate the material options available. Steel is common for its durability. Aluminum is lighter but may be less sturdy.

Tips: Always measure the installation area accurately. Mistakes can lead to costly delays. Consider the maintenance aspect too. Frequent inspections prevent minor issues from turning into major problems. Also, think about the aesthetics. A door that matches your branding can enhance business appeal.

Key Factors to Consider When Choosing Overhead Coiling Doors

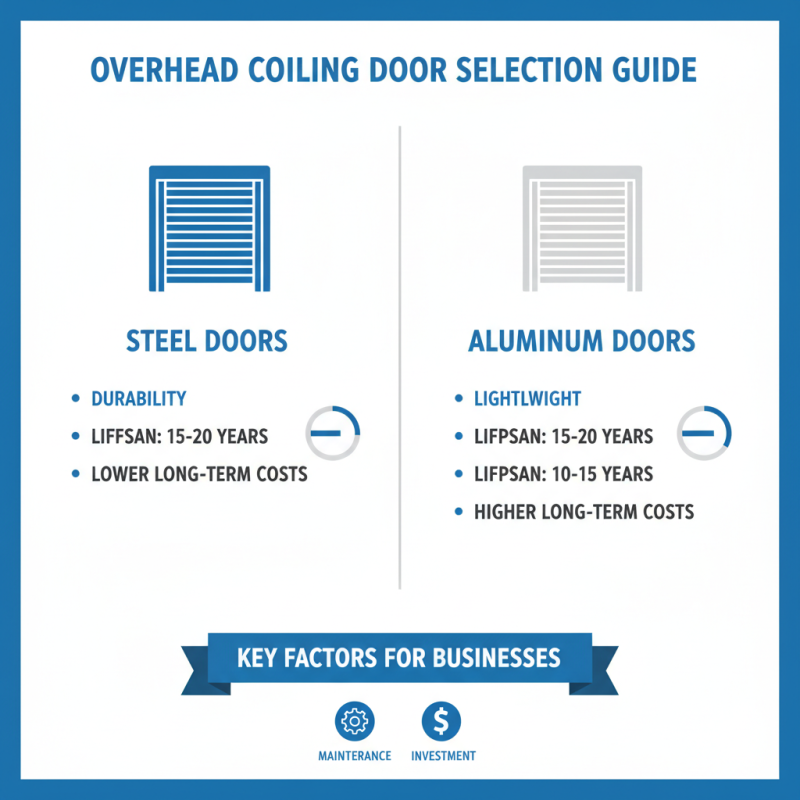

When selecting an overhead coiling door for your business, a few key factors are crucial. First, consider the material. Steel doors offer durability, while aluminum doors are lightweight. According to industry reports, steel options generally last 15-20 years, compared to aluminum's 10-15 years. This reflects on maintenance costs and potential replacements in the long run.

Security is another vital element. Strong coiling doors can deter break-ins. In a recent survey, 70% of businesses recorded fewer theft incidents after installing robust doors. Shape and size matter too. Doors need to fit the specific openings of your facility. Measure your spaces accurately to avoid issues during installation. Many companies underestimate this step, leading to costly rework.

Lastly, evaluate insulation properties. An insulated coiling door adds energy efficiency to your business. Statistics show that insulated doors can reduce heating and cooling costs by up to 20%. However, beware of the trade-off: thicker insulation can add weight, affecting the door's operation. Balancing these factors is essential for optimal performance and outcomes in your business environment.

Evaluating Material Options for Durability and Security

When selecting an overhead coiling door, the material plays a crucial role in durability and security. Common choices include steel, aluminum, and fiberglass. Steel is robust. It offers excellent resistance to impact and weather. According to industry reports, steel doors can last up to 30 years with proper maintenance. However, they may require regular upkeep to prevent rust. Aluminum is lighter and resistant to corrosion, making it suitable for locations with high humidity. Yet, it may be less secure than steel for high-risk areas.

Fiberglass doors are an emerging option. They provide good insulation and are resistant to dents and scratches. However, they might not withstand heavy impacts like steel can. Reports show that fiberglass has a lower lifetime expectancy, around 15-20 years. Understanding these material properties is vital. Different businesses have different needs. Balancing durability with security is essential. Ultimately, the right choice depends on specific environmental conditions and security requirements. Consider the unique demands of your business location.

2026 How to Choose the Right Overhead Coiling Door for Your Business? - Evaluating Material Options for Durability and Security

| Material Type | Durability Rating | Security Level | Maintenance Requirements | Cost Range |

|---|---|---|---|---|

| Aluminum | High | Medium | Low | $800 - $1500 |

| Steel | Very High | High | Medium | $1200 - $2500 |

| Fiberglass | Medium | Medium | Low | $600 - $1200 |

| PVC | Low | Low | Very Low | $300 - $800 |

| Composite | High | Medium | Medium | $900 - $1800 |

Assessing Insulation and Energy Efficiency Features

When choosing an overhead coiling door, insulation and energy efficiency should be a priority. A well-insulated door can significantly reduce energy costs. Look for doors with high R-values. This measurement shows how well the door resists heat flow. The better the insulation, the more comfortable your space will be.

Consider the door's material too. Steel and aluminum doors come in various thicknesses. A thicker door often provides better insulation. However, it can also be heavier, which may affect the installation and movement. Don’t overlook air leaks, as they can undermine energy efficiency. Sealants or weather strips can enhance performance.

Always assess the door's design and how it integrates with your building. Dynamic energy efficiency involves more than just the door itself. The entire entry system must work together. Installing the wrong type of door can lead to issues like condensation or drafts. Reflect on your specific needs and space before making a final choice.

Energy Efficiency Ratings of Overhead Coiling Doors

Installation and Maintenance Considerations for Longevity

When selecting an overhead coiling door, installation and maintenance are crucial for ensuring longevity. Proper installation not only enhances functionality but also extends the door's lifespan. It's essential to choose experienced professionals for the installation process. Amateur work can lead to misalignments, which create problems later.

Tips: Regular checks on the door's alignment can prevent future issues. A door that's not properly aligned may wear out prematurely. Make it a routine to inspect the door at least once a month. Look for any signs of wear, such as frayed cables or rust. Addressing these minor issues can save you from costly repairs.

Maintenance is equally important. Lubricate moving parts to keep them functioning smoothly. Neglect can lead to increased friction and operational failure. Understand the specific maintenance requirements for your door model. Some may need more frequent attention than others. Consider setting up a maintenance schedule for best results. It’s easy to forget, but staying proactive is key.

Related Posts

-

2025 Top Trends in Residential Garage Doors: Upgrade Your Home's Curb Appeal

-

10 Best Fancy Garage Doors to Transform Your Home's Curb Appeal in 2023

-

How to Choose the Best Residential Roll Up Garage Doors for Your Home

-

How to Choose the Best Overhead Coiling Door for Your Business Needs and Maximize Security

-

The Best 5 Residential Garage Doors for Security and Aesthetic Appeal

-

How to Choose the Best Rolling Garage Door for Your Home Safety and Style