How to Choose the Right Dock Seals for Your Warehouse?

Choosing the right dock seals can significantly impact warehouse efficiency. Dock seals are essential for maintaining temperature control. They create a barrier between the inside of a building and the outside elements.

When selecting dock seals, consider various factors. The specific requirements of your warehouse play a crucial role. For instance, think about the type of vehicles used. Will they be docked frequently? Different materials can also affect durability and cost. Sometimes, businesses overlook the climate conditions surrounding their facilities.

It’s not always easy to decide. You may need to balance functionality with budget constraints. Reflecting on past choices could help. Have your previous dock seals met expectations? Learning from past experiences can guide you. Finding the right dock seals is not a one-size-fits-all process. Take the time to evaluate your options carefully.

Understanding the Types of Dock Seals Available for Warehouses

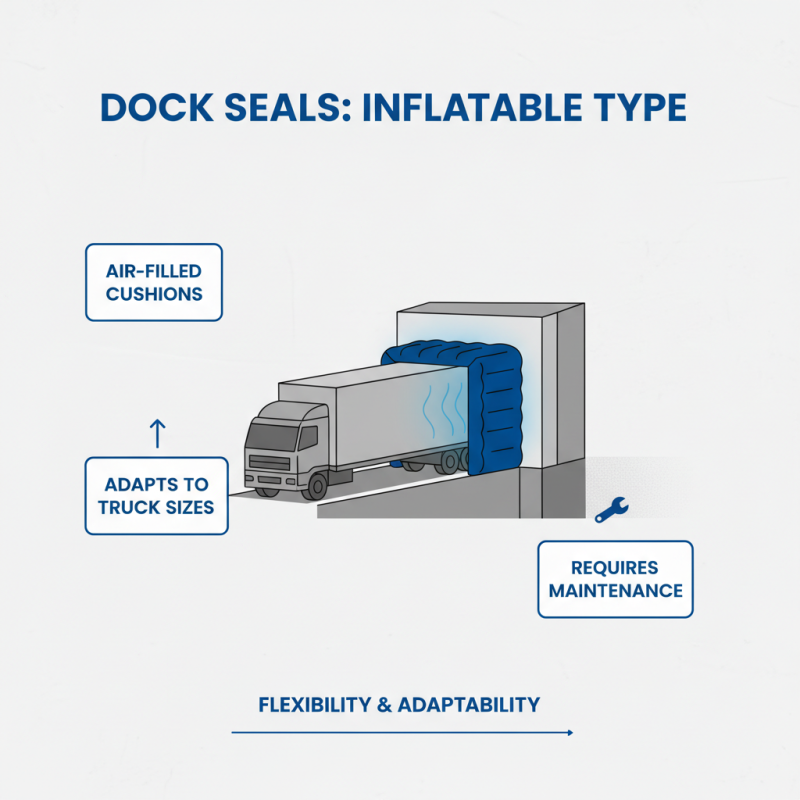

When selecting dock seals for a warehouse, it’s crucial to understand the various types available. One common type is the inflatable dock seal. This features air-filled cushions that create a tight seal against the vehicle. The inflatable design allows for flexibility and adaptability to different truck sizes. However, it may require regular maintenance.

Another popular option is the rigid dock seal. These are made from durable materials that provide a solid barrier. They can withstand harsh weather conditions. Yet, their lack of flexibility can be a challenge if the loading trucks vary significantly in height.

Tips: Consider the specific needs of your operations. Think about truck sizes, frequency of use, and weather conditions. Ensure the seal fits perfectly to minimize energy loss. Regular inspections are also essential to maintain integrity.

You might also encounter brush dock seals. These seals have a flexible brush material that accommodates slight movements. However, they may not provide as tight a seal as inflatable or rigid seals. Evaluate your facility's unique requirements before making a decision.

Evaluating the Size and Dimensions for Optimal Dock Seal Fit

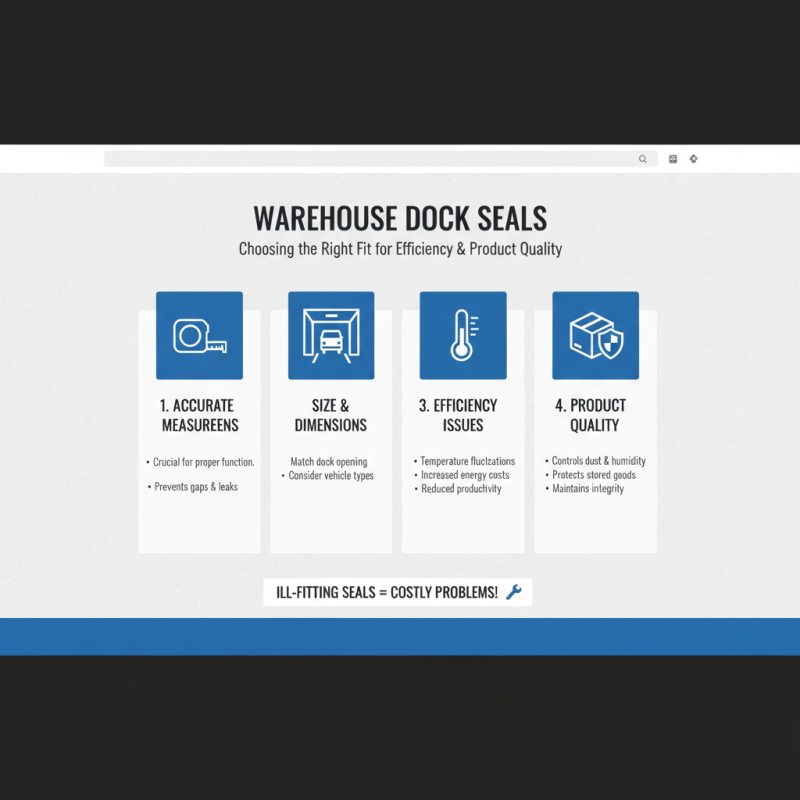

Choosing the right dock seals for a warehouse requires careful consideration of size and dimensions. Accurate measurements are crucial. An ill-fitting dock seal can lead to efficiency issues. It may cause temperature fluctuations or increased dust and humidity. This affects the quality of stored goods.

Measuring the height and width of the loading dock is the first step. Consider the types of vehicles used. For instance, trucks vary in height. If your dock seal is too tight, it may compress and tear. If it’s too loose, it can’t do its job effectively. Understanding the variability in loading heights is essential. Trusting standard sizes can be a mistake.

Pay attention to the material of the dock seals. It should withstand wear and tear. A lightweight material may not hold up well over time. Reflect on how weather conditions affect your warehouse. Extreme temperatures can wear down seals faster. Choose a durable seal that complements the dimensions and withstands local conditions. Each choice impacts the overall efficiency of your operations.

Considering Environmental Factors That Affect Dock Seal Performance

When selecting dock seals for your warehouse, environmental factors play a crucial role. Temperature fluctuations can impact the materials used in dock seals. Extreme heat can cause seals to deteriorate, while cold can affect their flexibility. It's essential to choose seals that withstand the local climate.

Consider the humidity levels too. High humidity can introduce moisture into the seal materials, leading to mold or mildew. This can undermine the seal's effectiveness and create safety hazards. Choose moisture-resistant options if your warehouse is in a humid area.

**Tips**: Always inspect dock seals regularly. Look for signs of wear and tear. Don't skip maintenance; it can save you money in the long run. Ensure proper installation to reduce potential issues. Before making a final choice, evaluate the seal’s resistance to various environmental elements.

In addition, be mindful of local wildlife. Pests may find their way into warehouse spaces if seals are not properly fitted. This issue often goes unnoticed until it becomes a larger problem. Assess how the chosen seal can minimize such risks for a safer, more effective warehouse environment.

How to Choose the Right Dock Seals for Your Warehouse?

| Key Factors | Description | Impact on Dock Seal Performance |

|---|---|---|

| Temperature Variations | Dock seals must withstand various temperatures that affect material flexibility and durability. | High heat may cause materials to degrade, while extreme cold can lead to brittleness. |

| Moisture Levels | Humidity and rain can lead to issues such as mildew and mold. | Moisture can deteriorate seal integrity and lead to leakage. |

| Wind Exposure | Strong winds can put stress on seals and potentially cause misalignment. | Improper sealing can lead to energy loss and increased heating or cooling costs. |

| Traffic Volume | High-frequency use can wear down seals faster than those with less use. | Wear may lead to early replacement needs and increased operational costs. |

| Seal Material | Different materials have varied performance attributes regarding weather resistance. | Choosing the right material can enhance durability and performance longevity. |

Assessing Cost vs. Benefits: What to Look for in Dock Seals

When selecting dock seals for your warehouse, weighing cost against benefits is crucial. A well-chosen dock seal can enhance energy efficiency. However, the initial investment can be significant. You must ask, are the long-term savings worth it? Consider how often your dock is used. High-traffic areas may benefit more from durable options. In contrast, low-traffic docks might need less expensive alternatives.

Evaluate the materials used in dock seals. High-quality options often last longer, but at a higher cost. A budget-friendly seal may wear out quicker, leading to increased replacements. Think about the climate. A good seal prevents air leaks, lowering energy bills. However, if you live in a mild area, the benefits may not justify the expense. Check the warranty as well. A lengthy warranty often indicates quality. Still, it’s essential to research before making a decision. Is the warranty truly reliable, or just a selling point?

Remember, the right choice is not just about price. It’s about finding a balance. You might find some choices puzzling or even frustrating. You could end up paying less now, but at what cost later? Reflect on your warehouse needs and choose wisely.

Cost vs. Benefits of Dock Seals in Warehouses

Installation and Maintenance Tips for Long-Lasting Dock Seals

Installing dock seals requires careful consideration. Proper alignment is crucial for sealing gaps. Materials should resist wear and tear. Regular inspections can prevent costly repairs. Look for signs of damage, such as fraying or tears. A damaged seal can lead to energy loss and pest issues.

Maintenance is another key aspect. Clean the seals regularly to remove debris. Dirt can cause wear over time. Lubricate moving parts to ensure smooth operation. This practice extends the life of your seals. Training staff on proper usage can prevent mishandling.

However, even with the best practices, issues can arise. Sometimes seals don't fit perfectly, leading to minor gaps. Not all installations will be flawless. Continuous observation and adjustments are necessary to achieve optimal performance. Making small changes based on observations can lead to better results in the long run.

Related Posts

-

Ultimate Guide on How a Handyman Can Expertly Fix Your Garage Door Issues

-

Why You Should Consider Garage Fix Solutions for Your Home Improvement Needs

-

The Best 5 Residential Garage Doors for Security and Aesthetic Appeal

-

Maximizing Your Home's Security: The Impact of Smart Garage Doors on Property Crime Reduction

-

Transform Your Home's Curb Appeal with Stunning Wood Garage Doors

-

The Impact of the 138th Canton Fair 2025 on Trends in Residential Garage Doors Industry